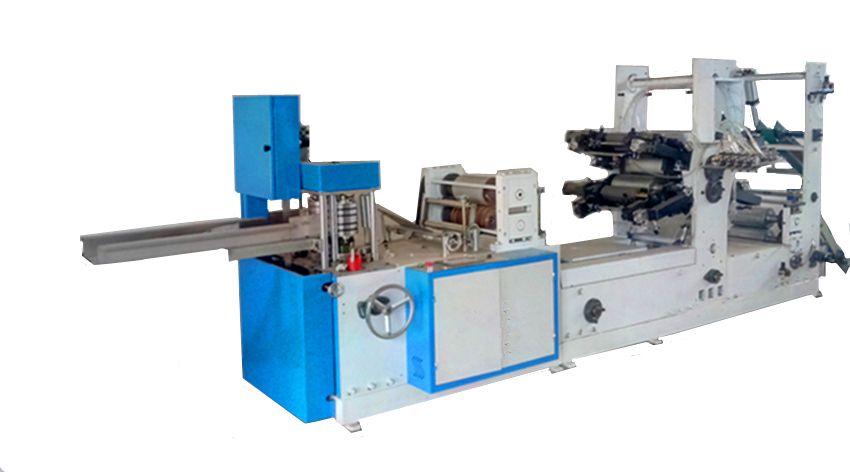

Multi-color Printing Napkin Paper Folding Machine

1.Technical specification

1. Size of folding roller: 165mm(width),material is chromium plated 45# steel .

2.Applicable roll quantity: 13~18 GSM(2ply/3 ply)tissue paper

3.Finished product open size : 330±2mm X 330 mm

4.Finished product folding size:165±2mm X165 mm

5.Folding type: 1/4 folding (1/8 fold can be customized)

6. Speed of folding: 400~600 pcs/min

7.The folding roller adopts clip type spring structure. The clip knife used 45# steel and the insert knife T10A steel.

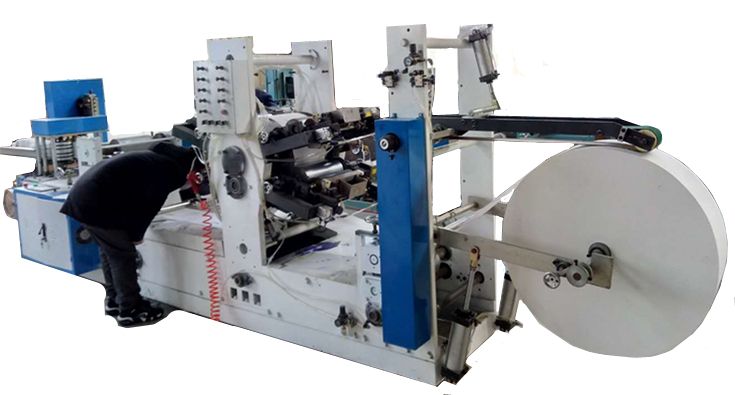

8.Color printing: Adopt CI type color printing unit. Four rubber rollers (rubber thickness 2.28 mm) share one bottom roller. The whole unit consists of porcelain roller, insert-type ink box,heating device,all-dimension adjustment control and auto-rolling .

9. Two calendaring rollers before color printing, speed, position adjustable.

10. Pneumatic raw material loading and unwinding.

11.Main frame is panel structure.

12. Embossing: steel to steel or steel to rubber

Transmission:

1. Main motor: 7.5 kw

2. cutting motor 1.1KW

3. Auto-ink rolling control 0.12 KW×4 Three sets of independent motor control

Control Unit:

1.Control unit: PLC control, speed regulation, touching panel control

2.Counting unit: Touching panel setting, photoelectric sensor, pneumatic stacking counting

3.Auto stop when running out of material or material breaks. Emergency button and jogging button.

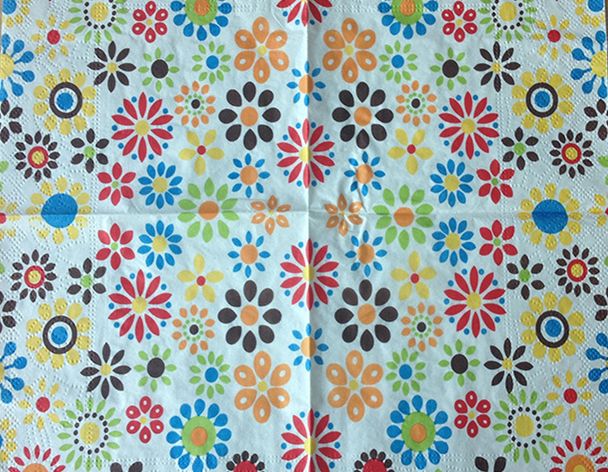

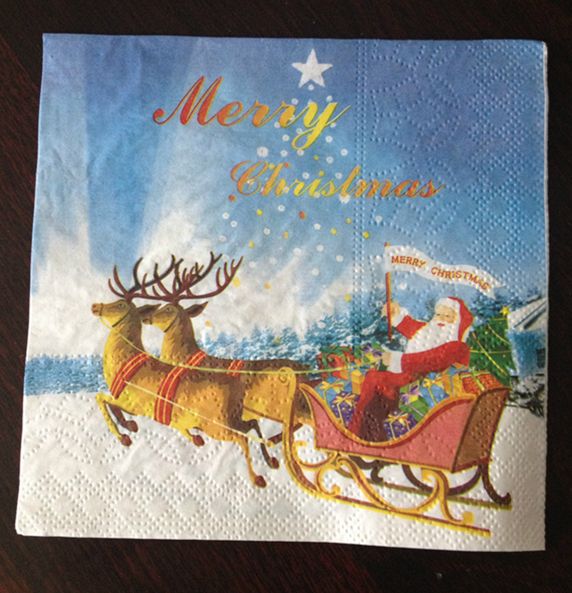

2. Products

3.Features

|

Insert type ink box This will prevent ink splashing in operation and saves about 4% of material and ink use.

|

|

Calendaring unit The material will go through the calendar roller before printing and it makes the printing effect better. |

| Four-color printing unit 1.Porcelain roller that enables better ink spreading and saves ink. 2.Independent motor that keeps the printing roller working and prevents drying. 3.Individual hand-wheel and inner design to adjust printing position while operation.

|

| Heating unit 1. Individual fan system and heating system are equipped to dry the ink quicker. 2. The total capacity of the design have been enhanced by 30%. 3. The speed remains the same for both with and without printer. |

| Color printing patterns: 1. The rubber patterns can be designed to create colors of different shades. 2. Certain colors can be produced through mixing, i.e: yellow+red=orange. A four-color machine can produce more than four colors with carefully designed pattern.

|

Adjustment for different size | |

| As you may know, the folding size of the napkin depends on the perimeter of the folding roller. In producing different size of products, we will make this folding unit changeable and offer different parts as per your required size. For instance, 330 folding unit and 300 folding unit,etc.

It takes about 30 min to change this part. |

| The other part to be adjusted is the printing roller. As the width of the raw material is different for different size, we will enlarge the printing rollers to fit for different printing size.

Pls note that, the size must be ordered before production. |

| All of the printing rollers are tightly meshed : 1. The paper will be tightly attached to the rollers and it prevents any stains or color-mixing in printing. 2. This design enables minor adjustment on the pattern position in operation without stopping the machine. |