Basic knowledge on unwinding and rewinding& Tension control principles

Today, we are going to talk about the major units related to the tension control and the tension control principles.

1. The major units related to tension control

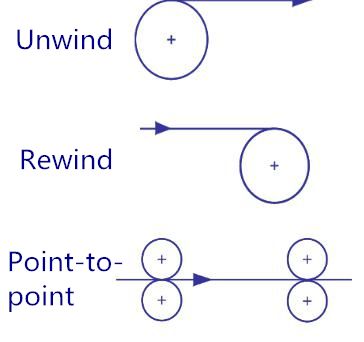

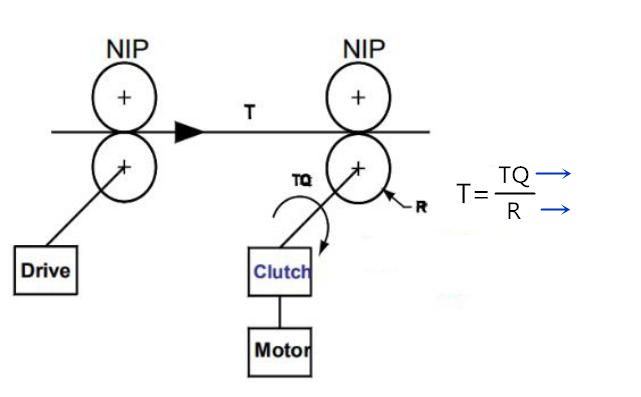

When we talk about the tension control unit on the machines, we are mainly referring to it for three major parts: the unwinding unit, the rewinding unit and the point to point unit(embossing or other unit where the material go through a set of rollers).

To start with, we will first introduce the difference of these units.

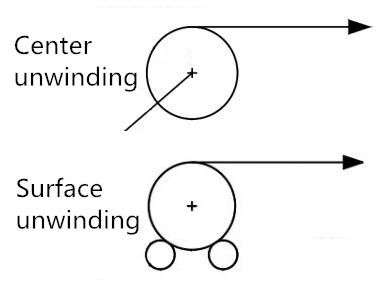

1.1 Unwinding unit: Unwinding unit will unwind and convey the material from roll to flat sheet. There are mainly two types of unwinding form: the center unwinding and the surface unwinding.

Center unwinding : the unwinding roller is directly driven by the motor. The tension of this unit should be varied as the diameter of the material is diminishing.

Surface unwinding: the material is unwinded through the friction from a side roller. It is also called passive unwinding. In this structure, the tension remains stable as the driving roller diameter is constant.

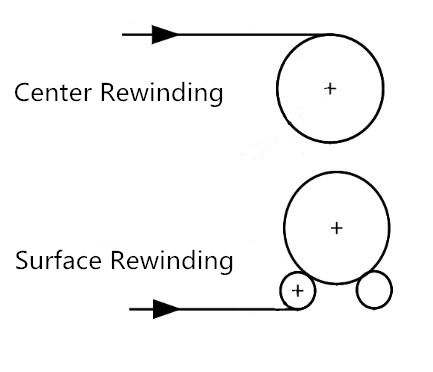

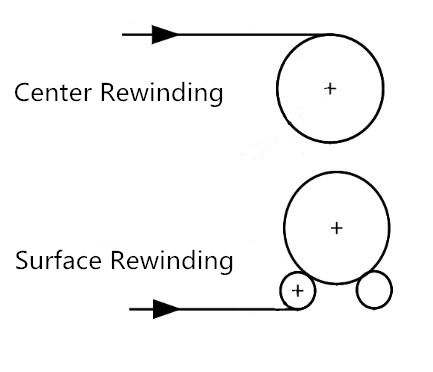

1.2 Rewinding unit: Rewinding unit will rewind the converted material into roll of certain diameter. We will discuss only the center rewinding and surface rewinding here today.

Center rewinding

Center rewinding is achieved by the directly controlled rewinding roller. As the diameter of the material roll is growing, the tension of this unit should be diminishing, which is known as the taper tension.

Surface rewinding

Surface rewinding is achieved through the friction between surface rewinding roller and the roll material, therefore, it is also called contacting rewinding or friction rewinding. In this unit, the core shaft is often air shaft. The speed of the rewinding is basically the same as the speed of the rewinding roller and it has nothing to do with the diameter of the roll being rewinded. Surface rewinding is also known as passive rewinding.

1.3 Point- to -point

Point- to- point application refers to the material go through certain rollers for embossing or calendaring purposes.

2. Tesion control priciples

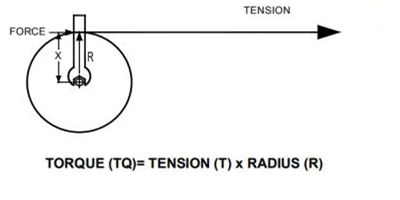

To explain the relationship between tension, torque and the distance, we introduce this formula as Torque= Tension* Distance. The viarant of the formula should be Tension= Torque/distance. (In the winding system, r refers to the radius of the material roll or the active roller)

Reference:

【1】高速收放卷控制

http://bbs.gongkong.com/D/200809/247889_1.shtml

【2】中心取卷和摩擦取卷张力控制

http://www.docin.com/p-1456428063.html

【3】表面收卷形式在复卷机

https://wenku.baidu.com/view/9a49ca1879563c1ec4da7101.html

【4】 MD330 收放卷张力控制

https://wenku.baidu.com/view/99fc9770195f312b3069a582.html

【5】收放卷张力控制定义及应用

https://wenku.baidu.com/view/5e4b833d0912a21614792936.html?rec_flag=default

【6】张力控制变频收卷程序方案

https://wenku.baidu.com/view/4948478302d276a200292e78.html

【7】收卷中的张力及其控制

https://wenku.baidu.com/view/ff379e31b90d6c85ec3ac622.html

【8】三菱张力控制系统

https://wenku.baidu.com/view/968152222f60ddccda38a0d4.html

【9】Basics of Web Tension Control Summary BY Darrel Whiteside