Technical specifications:

| Machine Model | SAN-FJ-C-1200-3500 |

| Raw Material Width(mm) | 1200- 3500 mm |

| Finished roll diameter | 60-150mm |

| Finished roll core diameter | 20-50mm |

| Raw material diameter | 1100mm |

| Raw material | 13-18 gsm double-ply;18-22 gsm single-ply;13-15 gsm tri-ply |

| inner dia.of parent roll core | Standardφ3' (76.2mm) unless otherwise specified |

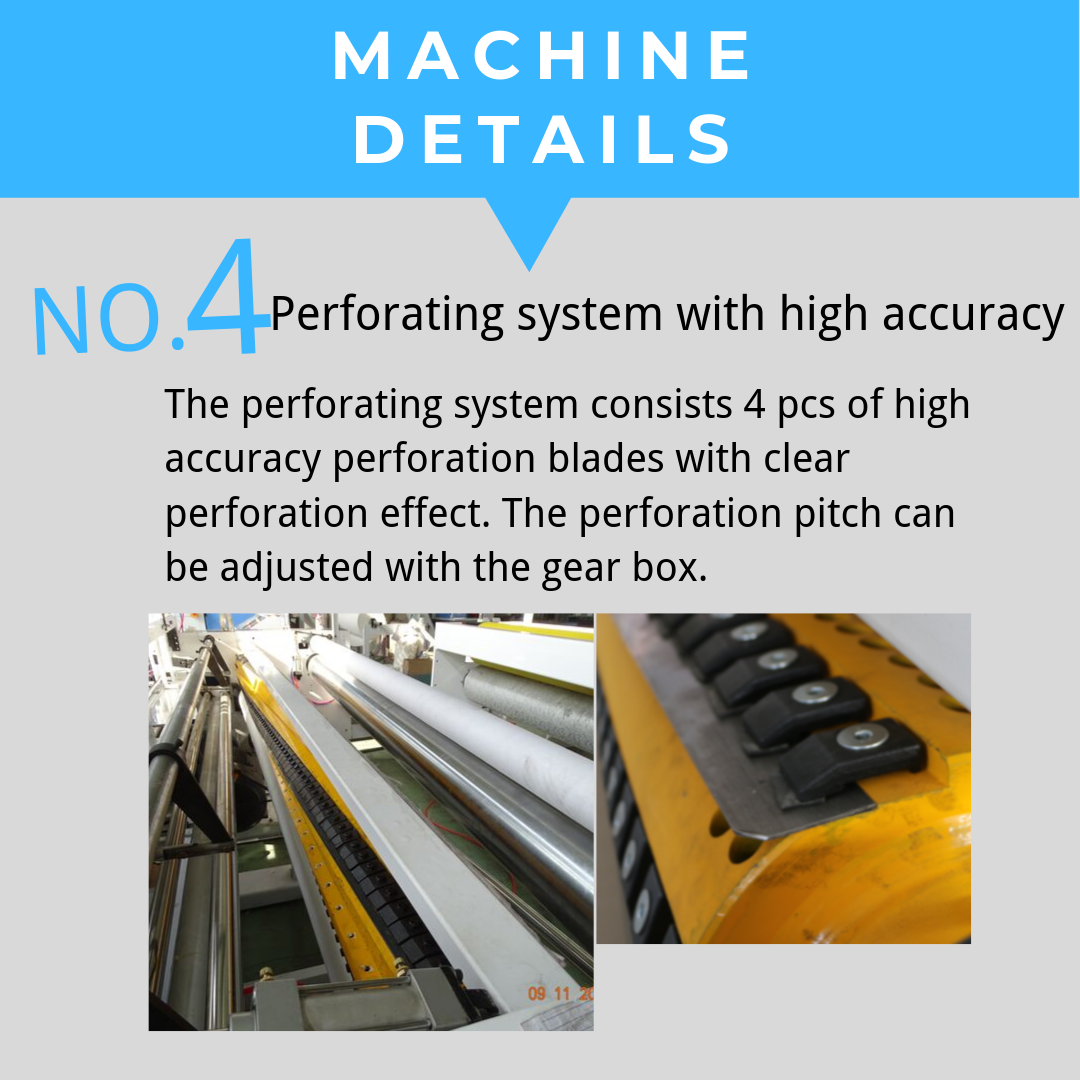

| Perforation pitch | 4 perforating blades 90-160 mm ; |

| 2 perforating knives 180-320mm | |

| Speed | 180-200 m/min |

| Pneumatic System | 3 HP air compressor |

| Power | 5.5-15 KW |

| Driving system | Independent servo driving |

| Option | |

| Embossing unit | Single ply; Double ply; Steel to steel embossing |

| Bottom embossing roller | Felt roller,wool roller ,rubber roller |

| Unwinding unit | 1-3 sets |

| Finished roll rewinding | Coreless rewinding system |

| Edge embossing | Steel to steel |

| Printing Unit | Single/dual color printing unit |

| Calendaring unit | Steel to steel, steel to rubber |

Features of Products

Main features:

1. Automatic core loading and replacing. The logs are automatically pushed out and new logs will be winded right afterwards. The cores can be changed to any sizes within one minute.

2. Automatic unloading system with mechanical arms pushing the products out. The minimum diameter of the product is 60mm.

3. Automatic trimming,gluing and sealing at one time. The machine adopts international popular trimming and sealing technology which leaves 10-18mm tails of the roll, reducing waste and cutting down the costs.

4. Advanced PLC programmable control technology is used to produce winding rolls which are tight at the beginning and getting loose along the way to avoid the problem that the cores are loose from the rolls after long time storage.

5. High-precision screwy perforation knife of four blades is equipped to make clear perforating, lower noises and wider range of the gear box.