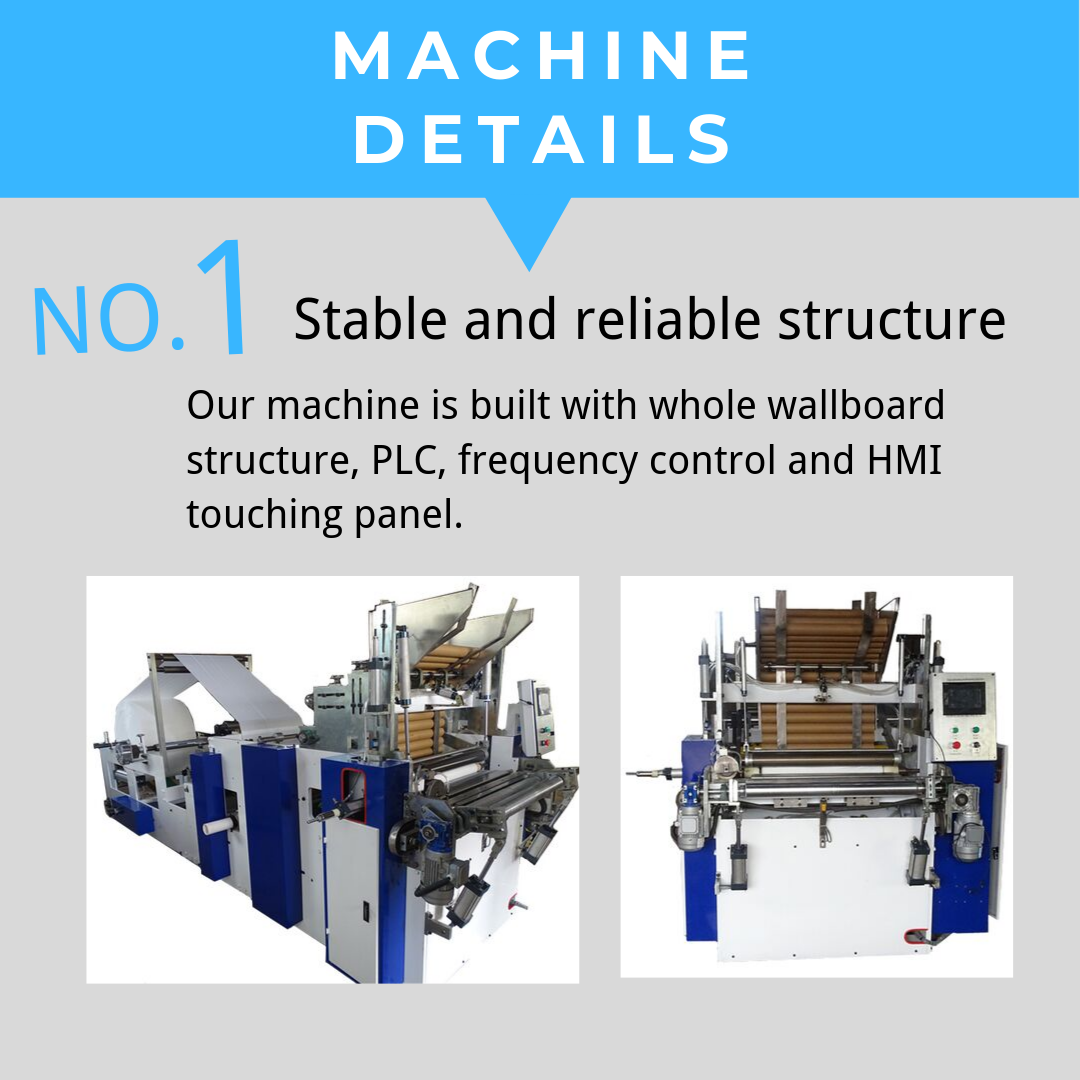

Full Automatic Table Cover Roll Making Machine

Click to check the video: https://youtu.be/ytIyzXC0WSs

This machine is used to produce the disposable laminated table cover roll making machine.

Working flow:

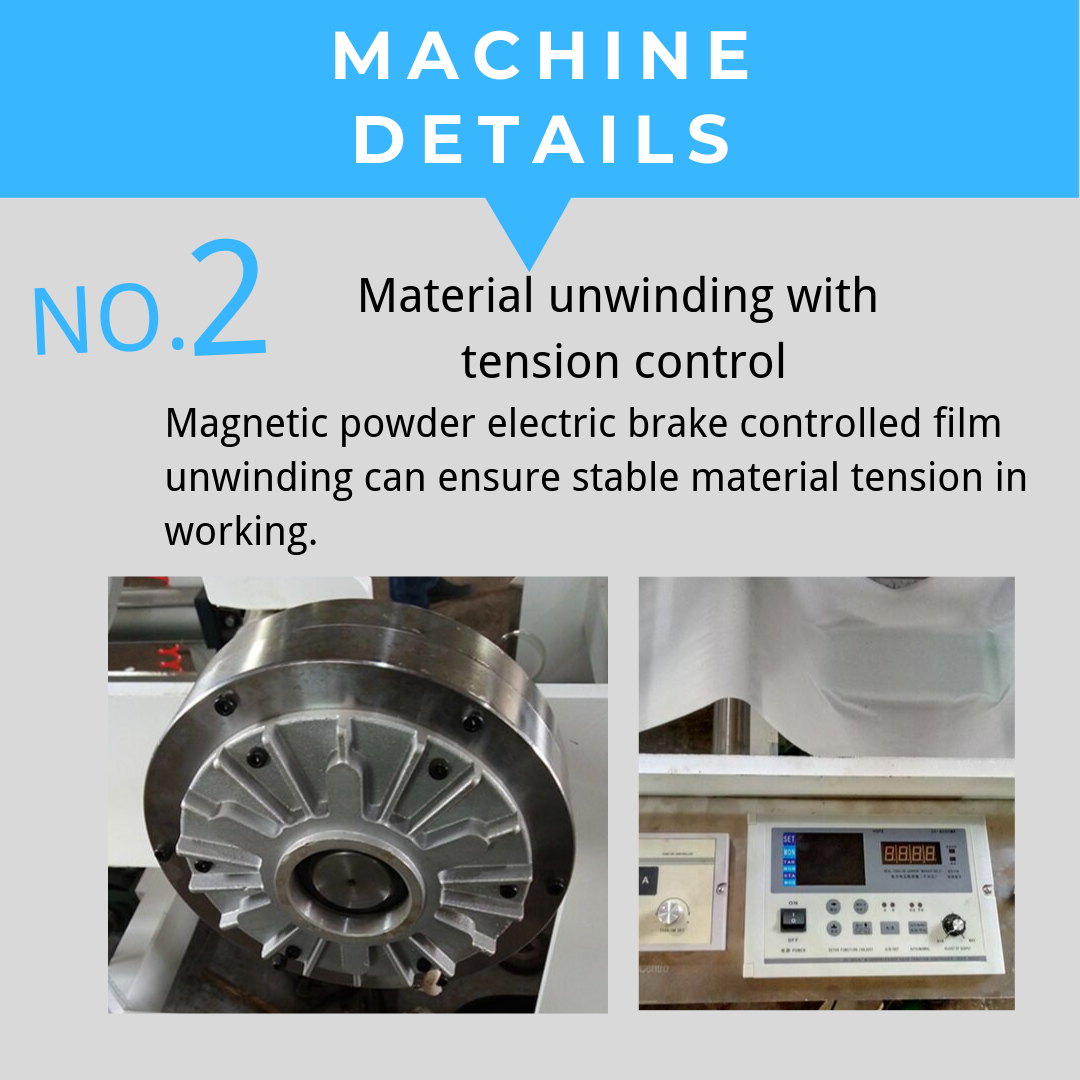

①Raw material pneumatic loading

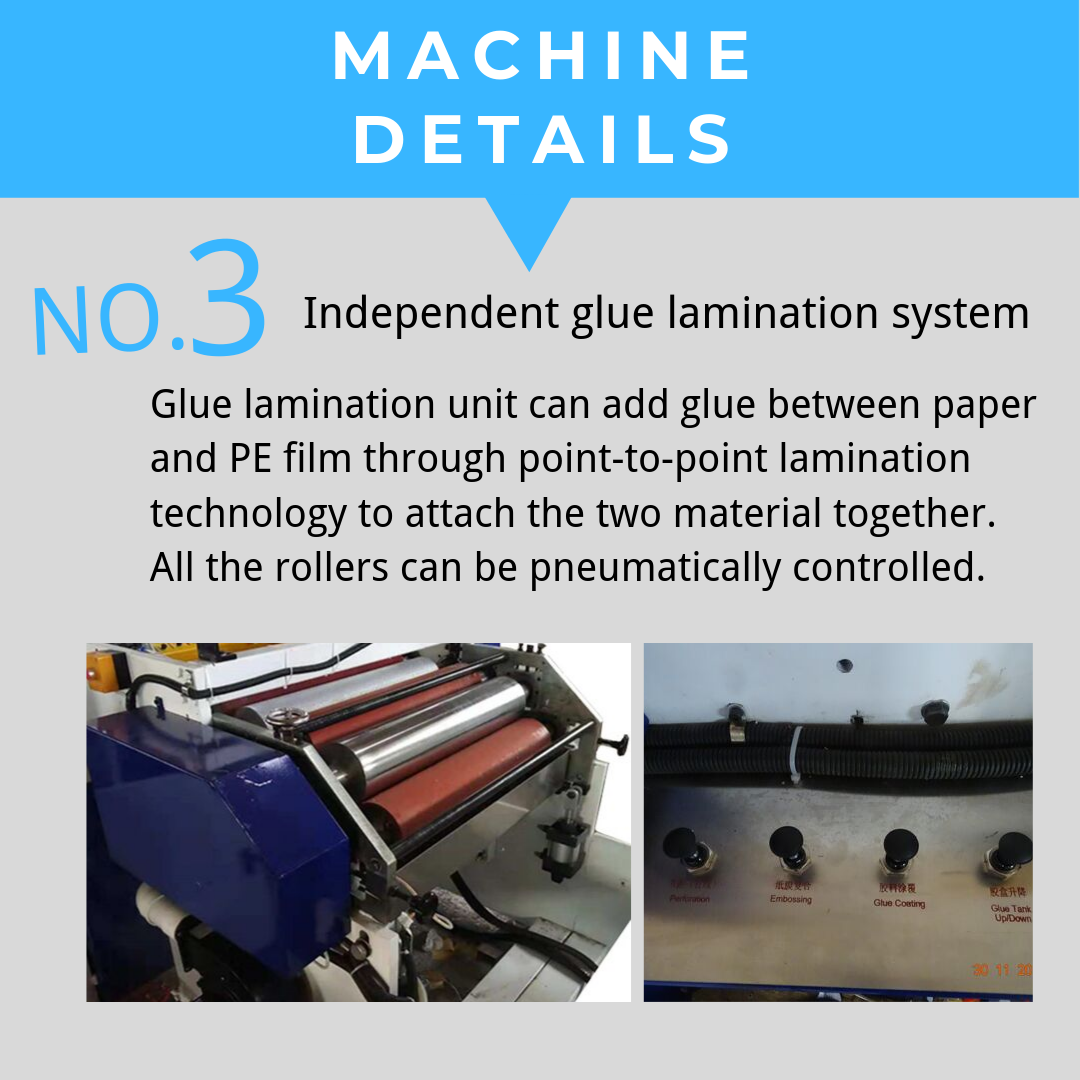

②paper flat belt driving

③1-6 color large size printing unit&drying unit

④plastic film magnetic powder tension control

⑤paper PE film lamination and composition

⑥center folding (optional)

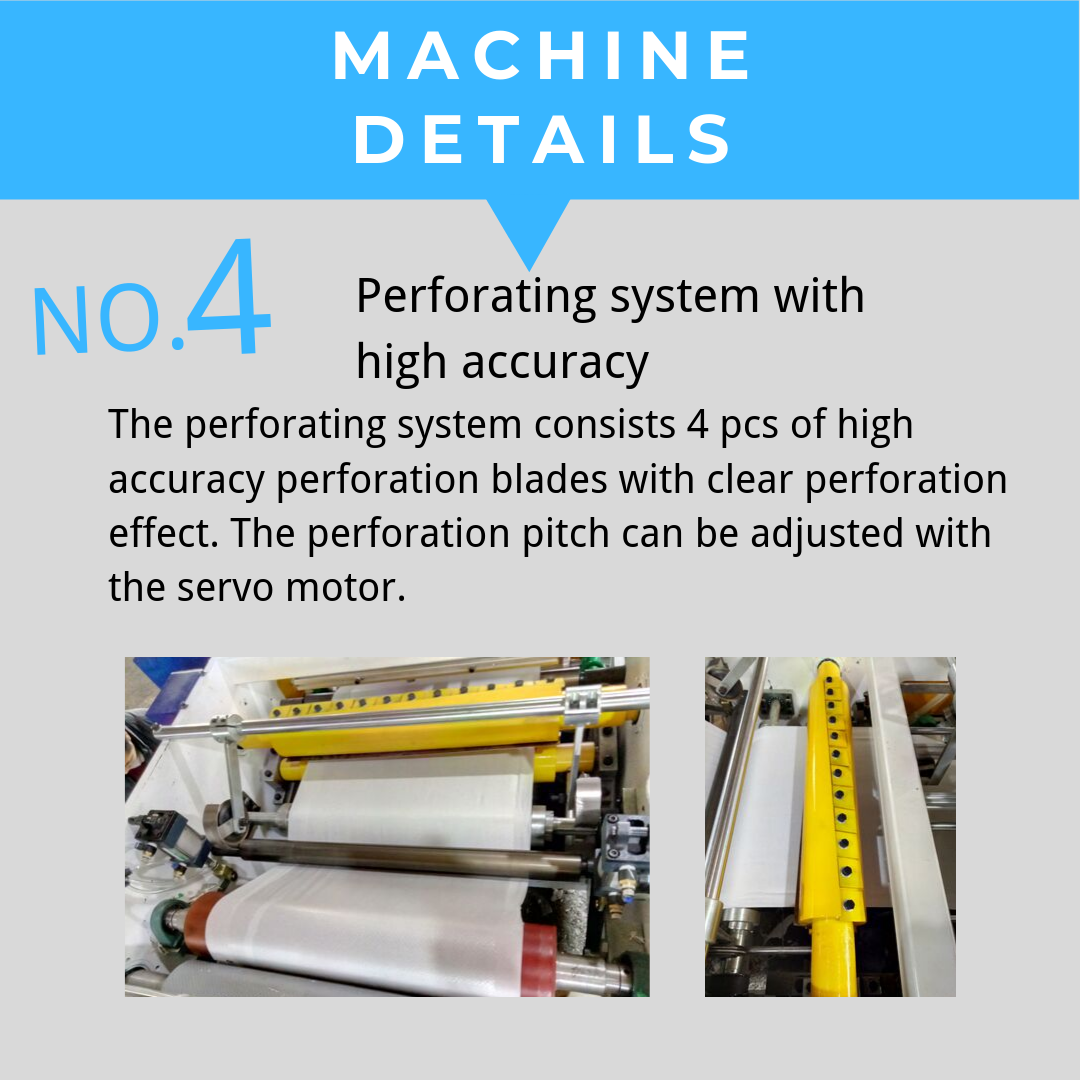

⑦servo-controlled auto perforation

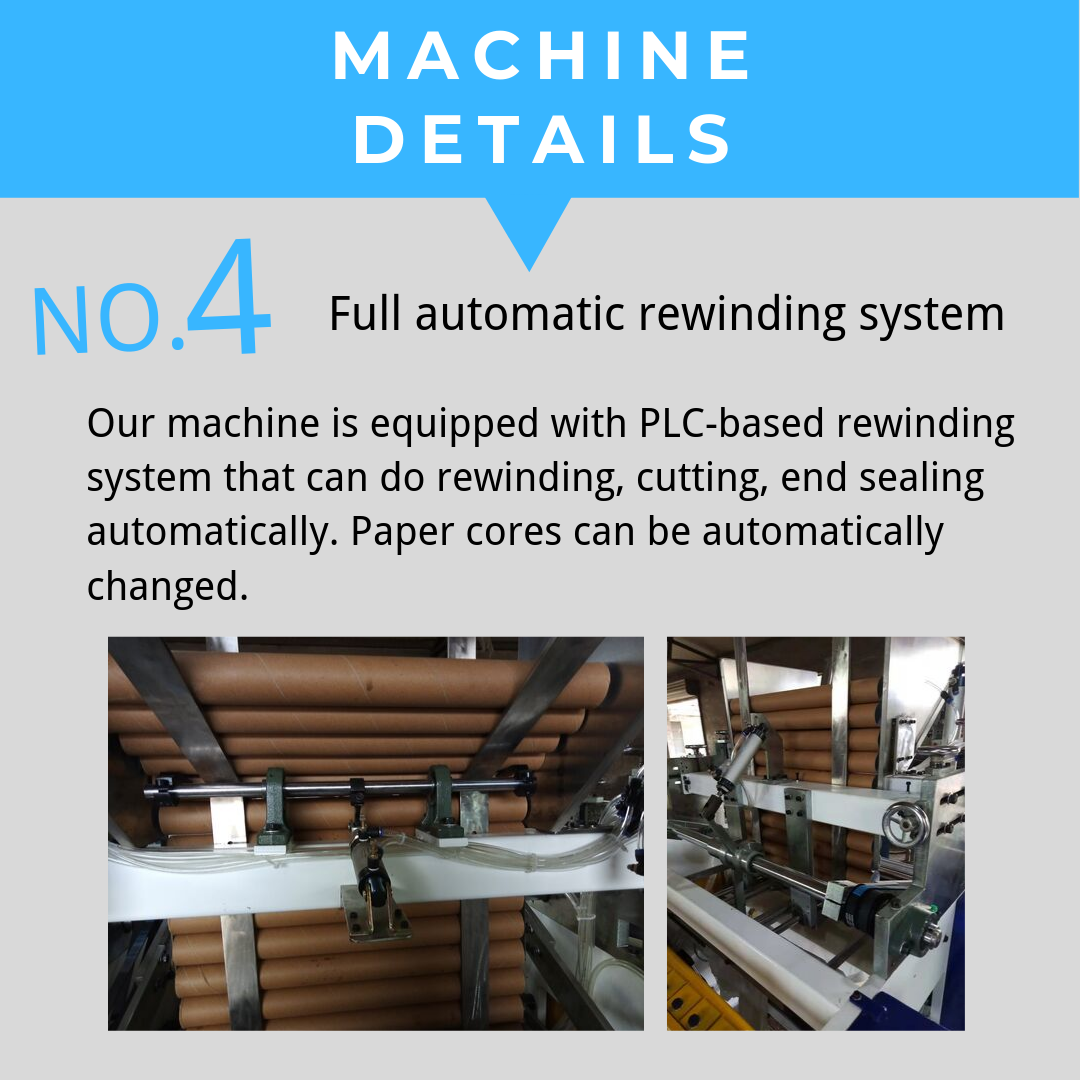

⑧auto rewinding

⑨auto cutting and core replacing

Equipment specifications

Model | SAN-DBJ-1000 |

Material | 1 Ply tissue paper and 1 ply HDPE film |

Tissue paper size | 800-1100 mm×Φ1100mm |

PE film size | 800-1100 mm×Φ500mm |

Paper core diameter | Φ76mm |

Rewinding roller width | ≥300mm |

Material loading | Tissue paper pneumatic loading |

PE film manual loading | |

Material feeding | Tissue paper by flat belt |

PE film by magnetic powder tension control | |

Control | PLC operation system and HMI control panel, servo system for perforating and color printing units |

Finished product paper core | Φ35-50 mm |

Rewinding large rolls diameter | Φ60-80 cm |

Rewinding small rolls with perforation diameter | Φ60-120 mm |

Perforation | Spiral knife perforation (Servo control perforation pitch adjustment) |

Tolerance ±3 mm | |

Adjustable range between 800-1300 mm | |

Pneumatic raw material loading | ≥0.6MPa Air compressor (provided by the user) |

Composition method | Glue lamination (without embossing) |

Color printing unit

| CI type color printing (leave space for 6 colors) |

Sealed ink box and scrapping knives | |

The heating unit 15 kw | |

1-5 color large size closed chamber and scrapper knife color printing | |

Working speed | 60-80 m/min (with lamination and color printing) |

Power | 9 kw 380 V 50 Hz |

Main body | Whole steel board |

Transmission system | Independent transmission/ Timing belt |

Rewinding unit | Auto rewinding |

End unit | Pressing roller and automatically tear off the last sheet. |

Optional function | 1. Printing pattern adding unit for multi-color printing. |

2. Automatic aligning unit | |

Electric parts brand for major units | Mitsubishi or Chinese reliable brands |

Explanations:

1. We offer two paper and plastic film combining method: heat embossing and glue lamination embossing.

2. We offer different plans based on your factory size, daily output requirement, and material.

3. All the electric components can be upgraded into designated brands.

4. For material loading, unwinding, and rewinding, we can offer both manual operation and automatic operation based on your requirement.