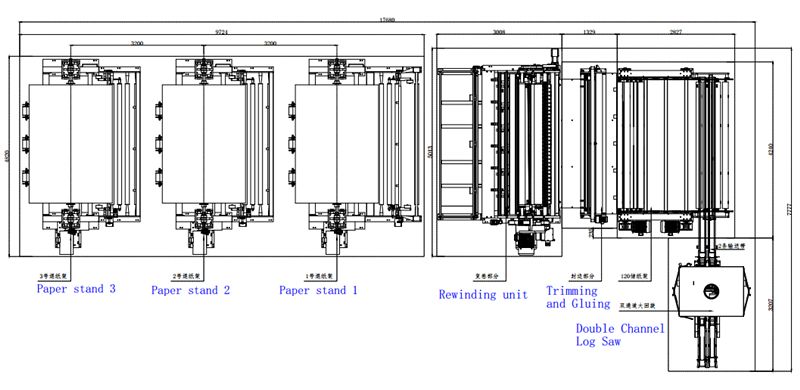

1. Features& Specifications:

1) Rewinding unit | |

1.1 | Max. parent roll width: 2800mm |

1.2 | Design speed: 350m/min for rewinding with core; 300m/min without core |

1.3 | Production speed: 300m/min for rewinding with core; 250m/min without core |

1.4 | Machine structure: Wall-type (thickness ≥40mm) |

1.5 | Finished roll diameter: 90-120mm with core; 70-120mm without core |

1.6 | Finished roll core diameter: 35-50mm |

1.7 | Perforating size: Adjustable |

1.8 | Perforating size tolerance: ±1mm |

1.9 | Paper break mode: positive break on the perforating area inside the machine. |

1.10 | One rotating perforating roll with 6 helix anvil blades mounted on it. |

1.11 | One fixed perforating roll with 2 dented blade mounted on it. |

1.12 | Perforating unit angle adjusting: manual |

1.13 | Automatic inducting system to protect the perforating roller. |

1.14 | Rewinding mode: tri-rollers, non-stop continuously rewinding. |

1.15 | Drive on rider roller: servo motor |

1.16 | Rider roller elevator: pneumatic control |

1.17 | Drive on bottom rewinding roller: servo motor |

1.18 | Log diameter controlled by pneumatic & electronic system |

1.19 | Paper cores: will be automatically transferred to the rewinding section through the core accumulator |

1.20 | Paper break inspection: with paper break inspection system (located between perforating unit and rewinding unit) |

1.21 | Paper-spread roller : Banana rubber roller |

1.22 | Min. Air pressure required: 0.4 Mpa |

1.23 | Air-consumption: ≤1000 L/ 8hr |

1.24 | Driving: individual motor driving, Servo motor, timing belt, flat belt. |

1.25 | Rider roller control: timing belt, servo motor |

2) Unwinding unit | |

2.1 | Max. parent roll width: 2800mm |

2.2 | Unwind stands quantity: 2 sets |

2.3 | Max. parent roll diameter: 1500mm |

2.4 | Parent roll core inner diameter: 3” |

2.5 | Unwinding system: 2 pneumatic-controlled flat belts. |

2.6 | Paper-spread roller: Banana roller |

2.7 | Speed adjusting on unwind system: Inverter synchronize speed adjusting |

2.8 | Jumbo roll fix: by spindle and chucks. |

2.9 | Jumbo reels alignment adjusting: by pressing the electronic button |

2.10 | Tension control: via main touch screen to set/adjust the tension. |

2.11 | Reel-unwinding mode: driven by Motor, the middle back stand(if there are 3 stands), unwinding direction can be changed. |

2.12 | Paper break detection: with paper break detector system |

2.13 | Power: 5.5 KW*2 |

2.14 | Min. Air pressure required: 0.4 Mpa |

2.15 | Air-consumption: ≤200 L/ 8hr |

2.16 | Structure: Integrated structure, jointed by welding steel. |

2.17 | Driving: individual motor driving, servo motor, timing belt and flat belt. |

3) Embossing unit | |

3.1 | Max. parent roll width: 2800mm |

3.2 | Pressure adjust: pneumatic |

3.3 | Embossing type: point to point or point to face (decide by buyer) |

3.4 | Embosser pattern technology: Etched (if require Engraved technology, price will be different) |

3.5 | Rotating on glue anilox roller: driven by individual motor |

3.6 | Motor power: 15 KW |

4) Tail-sealing unit | |

4.1 | Max. parent roll width: 2800mm |

4.2 | Log diameter: 90-150mm |

4.3 | Tail length: 10-30mm, adjustable |

4.4 | Tail length tolerance: ±5mm |

4.5 | Speed: 18 logs/min. |

4.6 | Gluing unit: spray glue |

4.7 | Glue material: water-based glue |

4.8 | Driving: individual motor, timing belt, flat belt |

4.9 | motor power: ≤5 KW |

4.10 | Min. air pressure required: 0.6Mpa |

4.11 | Air consumption: ≤2000 L/ 8hr |

5) Log accumulating& Log unloading unit | |

5.1 | Max. parent roll width: 2800mm |

5.2 | Log diameter: 90-150mm |

5.3 | Log storage: 150 logs. |

5.4 | Loading speed: 20 logs/min. |

5.5 | The log will be automatically transferred from the tail-sealer to the accumulator. |

5.6 | Log unloading: paper logs will be automatically unloaded to the log saw cutter, 1 or 2 logs can be selected. |

5.7 | Power: 1.5 KW* 2 |

6) Log saw cutting unit | |

6.1 | Max. parent roll width: 2800mm |

6.2 | Cut off length: any size, with servo control, with ±0.5mm tolerance. |

6.3 | Cutting surface vertical tolerance: ±0.5mm |

6.4 | Lanes: 2 lanes |

6.5 | Machine speed: 130-150 cuts/min. |

6.6 | Blade diameter: 610mm |

6.7 | Blade sharpening: Automatic pneumatic blade sharpening system |

6.8 | Power: 7.5 KW, servo motor: 0.75 KW. |