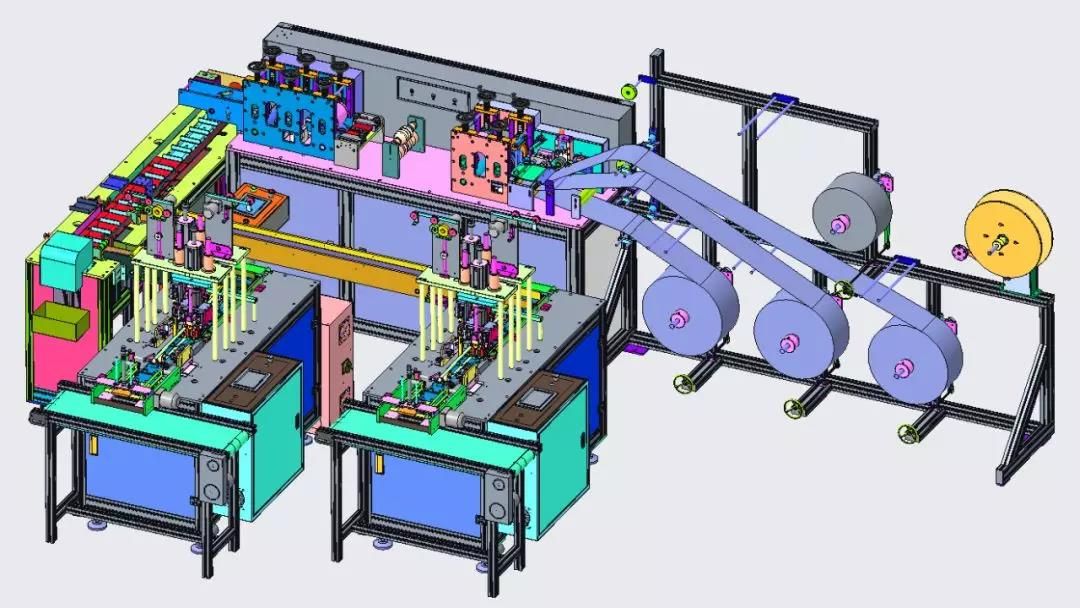

Full automatic face mask machine analysis

The full automatic face mask machine consists of the following parts:

1. Raw material unwinding unit

2. Nasal strip inserting unit

3. Flat sheet folding machine

4. Dispatching unit * 2 sets

5. Earloop sewing unit*2 sets

6. Finished products conveying unit*2 sets

Machine details :

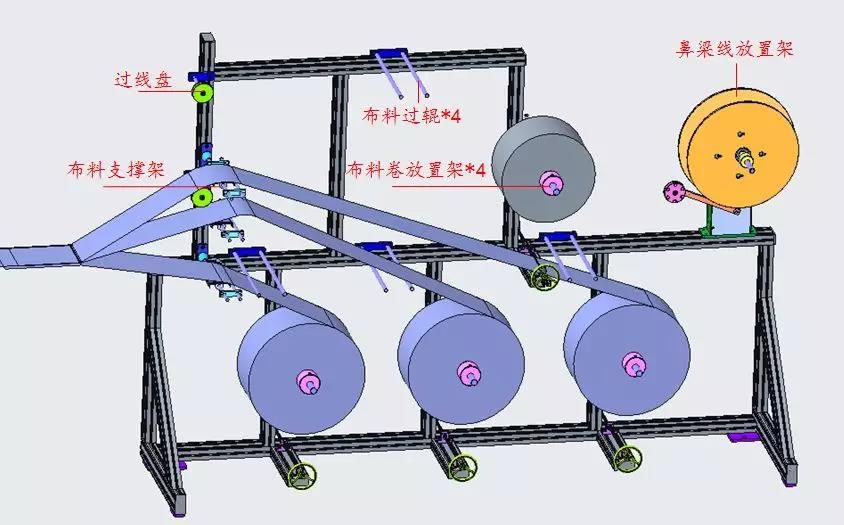

1. Raw material unwinding unit

1.1 Non-woven material unwinding unit

This machine has 4 back stands for non-woven material and one back stand for nasal strip. Therefore, the machine can produce max. 4-ply disposable face masks.

The unwinding unit for non woven material consists mainly of the support pole, the fix blocks, and the material adjusting unit with hand-wheel, leading screw, screw base, limit control unit,etc.

We can adjust the raw material position in four directions.

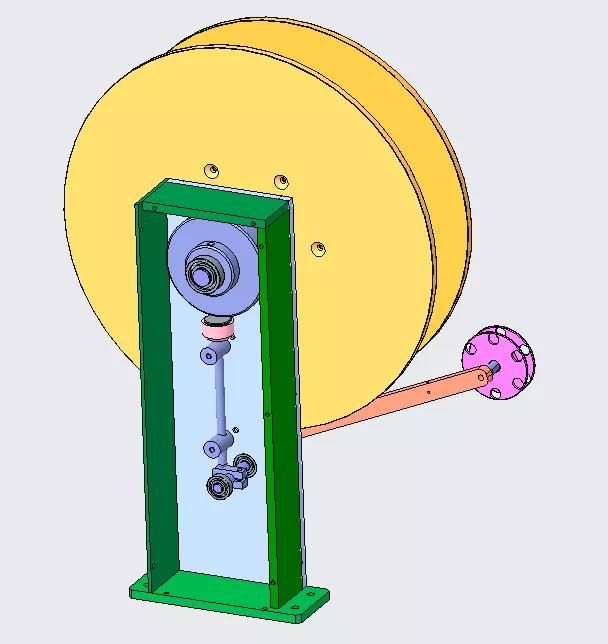

1.2 Nasal strip unwinding unit

There is no actuating unit for the nasal strip unwinding unit. This unit works along with the driving& nasal strip inserting unit. The nasal strip will go under the smaller unwinding wheel and lift it up when the strip is tight if there is not enough material in the inserting unit. The lifted wheel will rotate and activate the locking unit to rotate the larger unwinding wheel again.

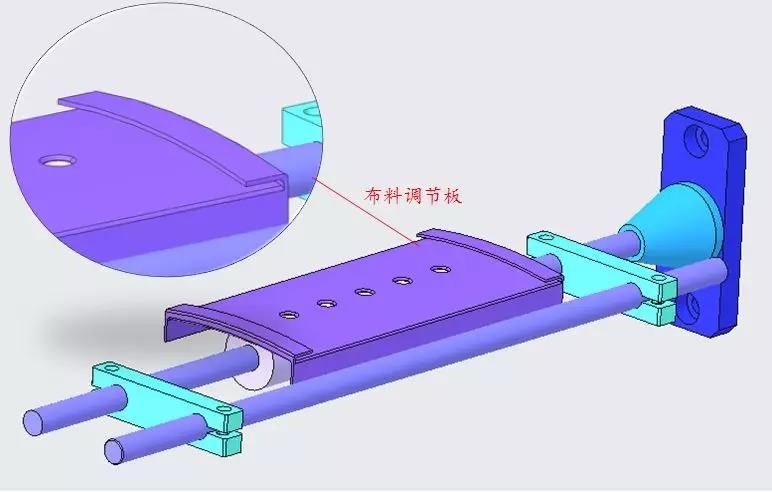

1.3 Non-woven guiding and support unit

The two sides of the adjusting panel are folded so the non-woven material can go through it. It is used to fix the position of the material in the machine running.

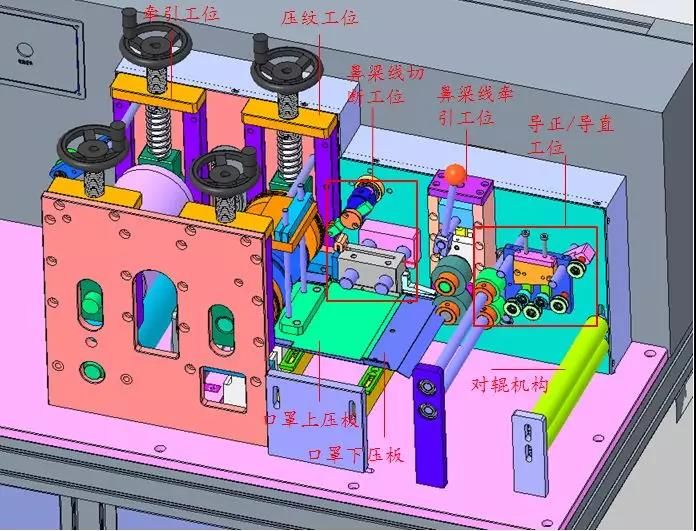

2. Nasal strip inserting unit

In this unit, the nasal strip will be inserted in the mask and two sides of the mask will be sealed by the ultrasonic sewing head. The major components are: the nasal strip guiding&positing control unit, nasal strip cutting unit, mask side sealing unit and material driving unit.

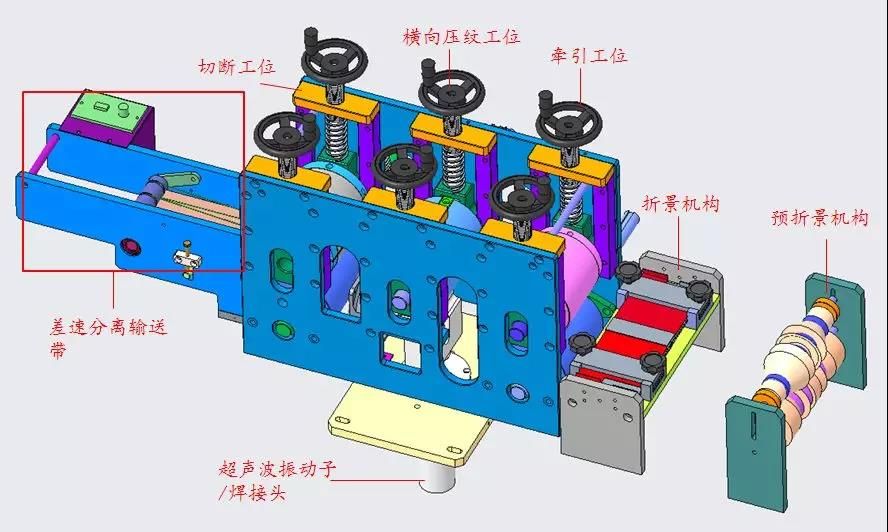

3. Flat sheet folding unit

After this unit, the face mask will be folded with 3-4 curves in the center that will give enough space to cover people’s faces. There will be two sets of folding unit, driving unit, side sealing unit, cutting unit and the conveying unit. This sealing function is also achieved with the ultrasonic method.

Above are the basic structure for the semi-automatic face mask machine.

The nasal strip inserting unit and the folding unit share one set of the power system of a motor and a reducer.

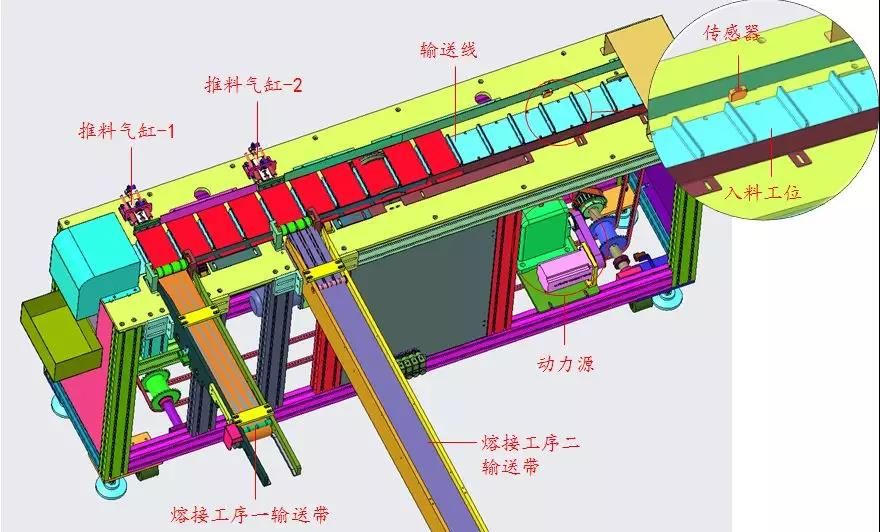

4. Dispatching unit * 2 sets

The flat sheets from the previous step will be dispatched onto two conveying units. The sensors will activate the conveying belt when detects a mask. The pushing cylinder will further push the mask onto the conveying belt to the sewing unit.

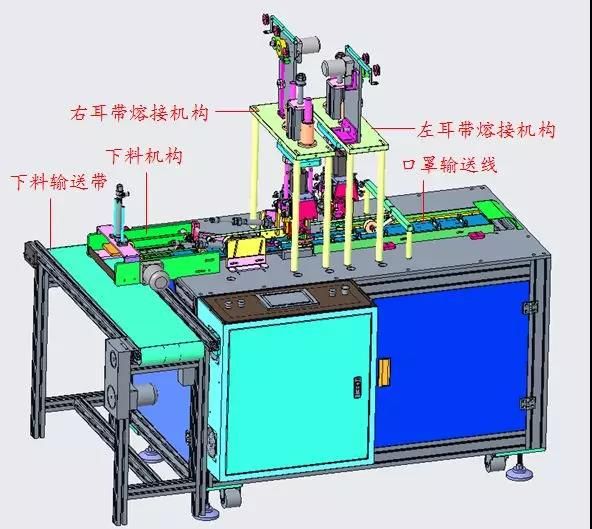

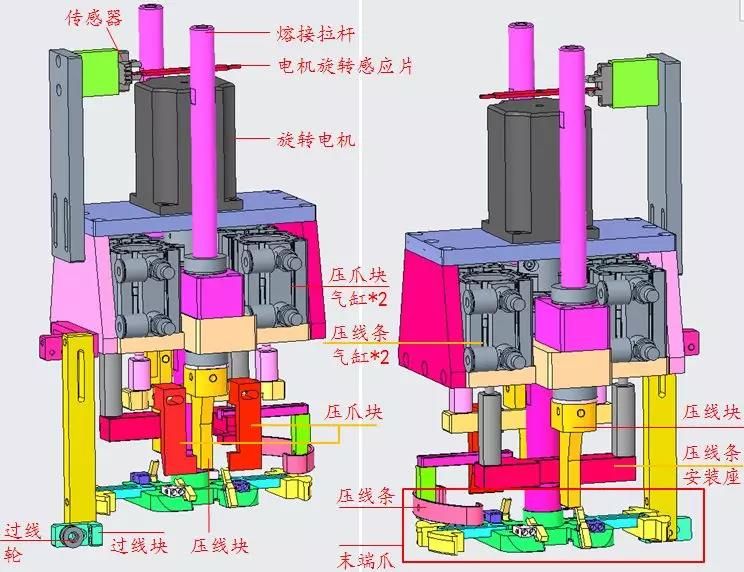

5. Earloop sewing unit*2 sets

The ear loops will be sewed on both sides with an ultrasonic sewing unit and then pushed out on the output conveying unit.

The ultrasonic sewing unit can be further developed into three parts: the ear loop feeding unit, the sewing unit, and the cutting unit.

The ear loop will be unwinded and guided onto the sewing unit, the cutting unit will cut off the loop and the sewing unit will be sewed the ear loop on the face masks.

The ear loop unwinding unit shares a similar structure with the nasal strip unwinding unit.

5.1 The ear loop feeding unit

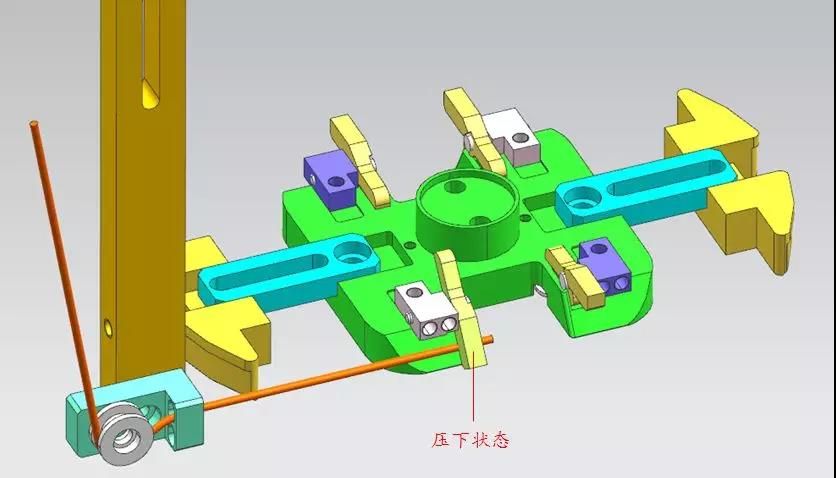

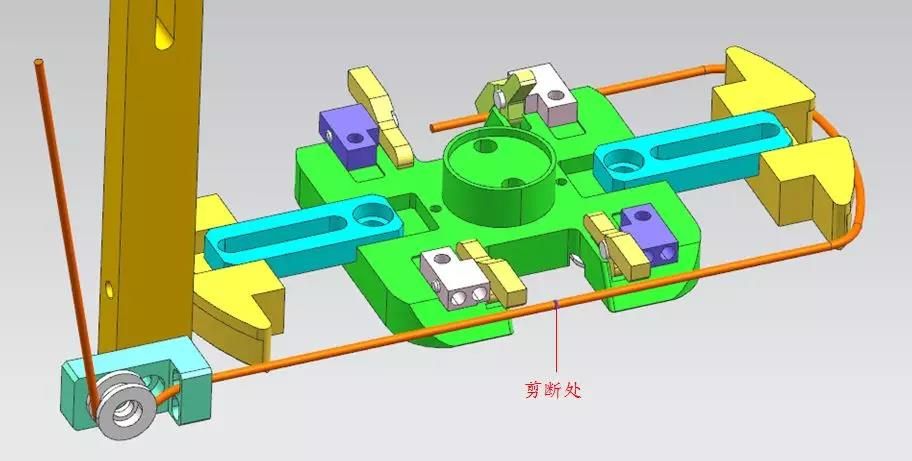

One side of the ear loop will be pressed under the clutch and activate the sensor. The rotation motor will then turn the whole unit 180 degrees counterclockwise. Sewing unit cylinder will press down the panel and fix the loop. The ear loop cutting unit will cut the loop at a given position and the cylinder will press again until the loop is sewed on the mask. At the same time, the panel will also press the clutches back to its starting position.

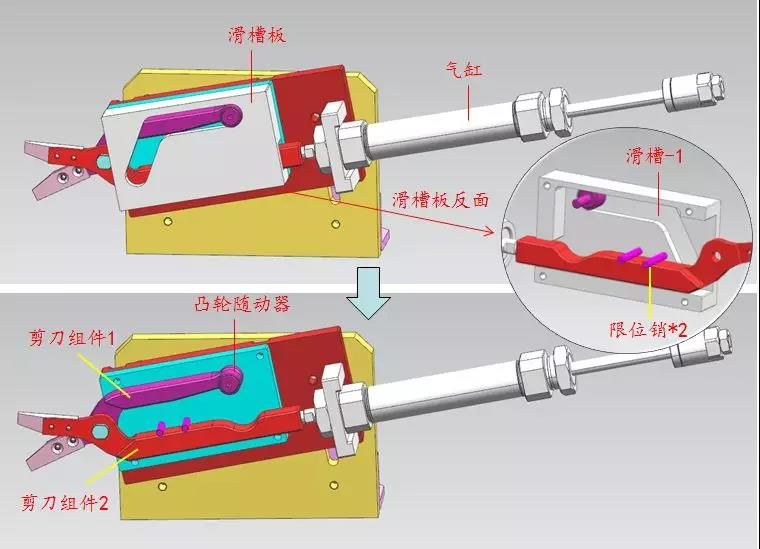

5.2 Earloop cutting unit.

The cutting unit is driven by the cylinder. Cutting unit one is pushed forward by the cylinder and cutting unit 2 will move along the fixed channel. Then the scissor will cut off the loop.

5.3 The ear loop sewing unit.

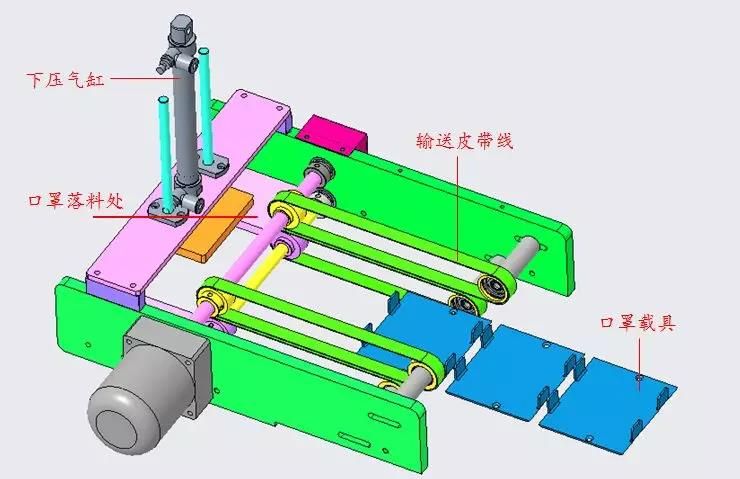

6. Finished products conveying unit*2 sets

The finished face masks will be conveyed by the driving belt and dropped on the conveying belt by the pressing cylinder. There is a sensor on this unit to count the number of the masks and move the conveying belt in one working stroke after marked a given quantity.