On printing unit of napkin/non-woven folding machine-2

Laure@sanmachinery.com +86 15764241004

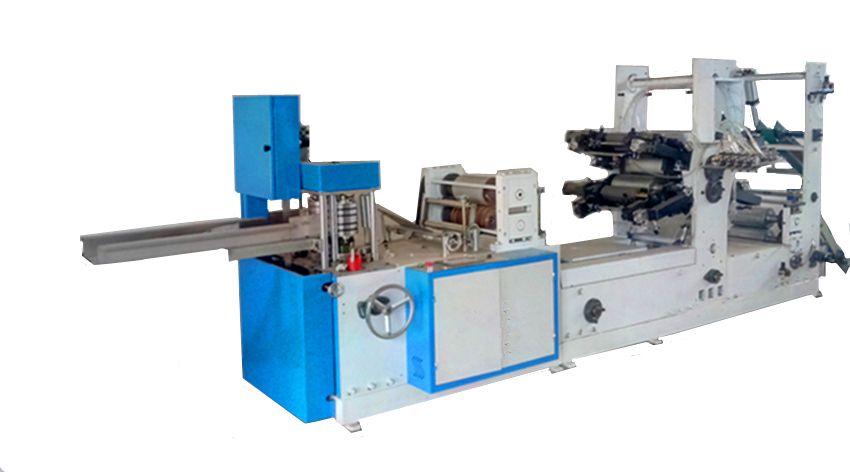

As mentioned in the previous article, there are three different printing unit design for the paper/non-woven folding machine. As the group type printing design is usually used for color printing of more than 8 colors, it is more economical for printing specialized factories. For the color printing unit on napkin paper or non-woven products, Stack type and CI type are more commonly adopted. Today, SAN MACHINERY is going to explain you in details the structure of stack type and CI type printing unit and help you compare the advantage and disadvantage of the two structure.

Basic structure

The printing unit consists of the roller group and the ink system.

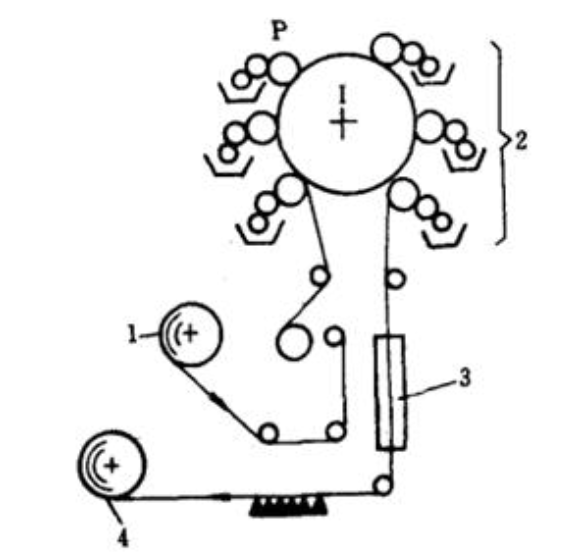

1.Roller group

The roller group is composed of the printing roller and the pressing roller.

1.1 Printing roller

Printing roller is used to hold the printing pattern and is usually made of seamless steel tube. The printing pattern can be put on the roller with both double side glue.

1.2 Pressing roller

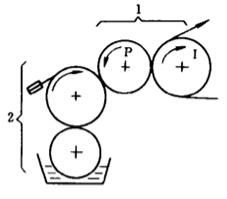

Pressing roller for stack type(6 color type)

Stack type and Group type share the same pressing roller design. The diameter of the printing roller and pressing roller should be the same to avoid color stain or pattern malposition. The pressing roller gives to the printing roller should also be carefully designed to main ideal printing pressure.

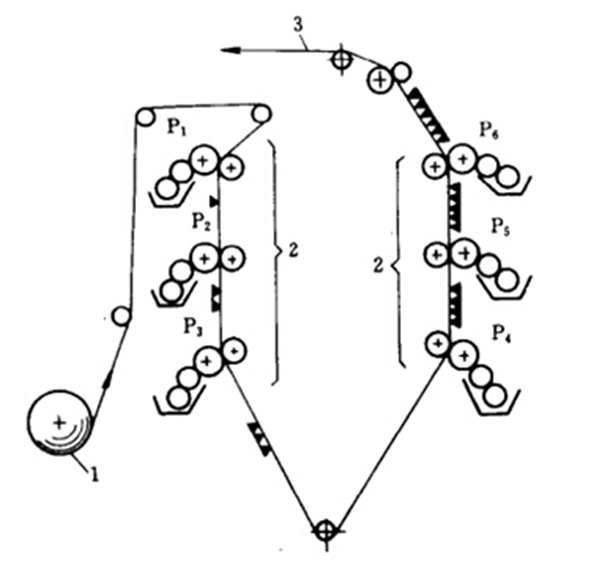

Pressing roller for CI type(6 color type)

Pressing roller is the key component of CI type printing structure. This pressing roller will give certain pressure to all the color printing rollers around it and therefore, it is required to be built with high-accuracy in size, shape and position.

2.Ink system

The ink system is usually composed of two ink rollers or one ink roller with scraping blade. The ink roller, also known as anilox roller is the most important part of the ink system. There are two designs in this system: rubber ink unit with anilox roller and anilox roller with scraping blade.

Comparison

Model | Advantage | Disadvantage |

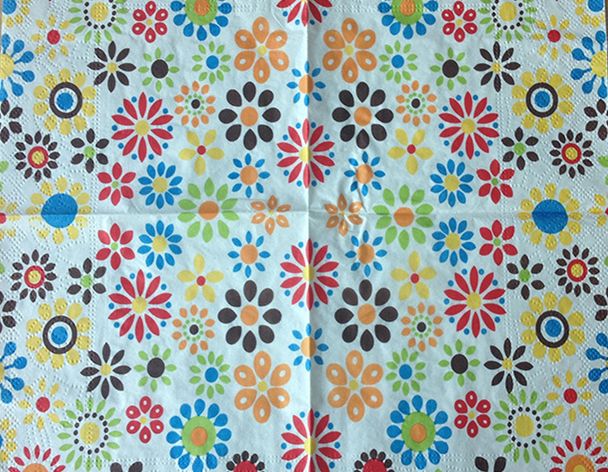

Stack type

| 1. Stack type is the commonest printing design used for multi-color printing napkins with advanced technology. 2. Stack type can be used to print on both sides. 3. The material will go through independent color printing unit and it gives enough time for the ink to dry. 4. Stack type is suitable for patterns of large size. | 1. Stack type takes much space as it has to give independent printing unit for each color. 2. The material is not very closely attached to the printing roller and the material may be stained in printing. |

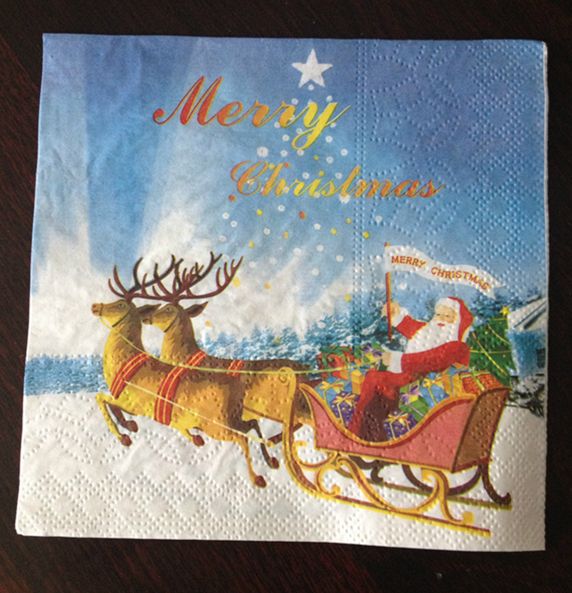

CI type

| 1. The CI type is of compact design and takes less space than stack type. 2. The material is closely attached to the ink rollers and it prevent color stain in printing. 3. The transmission of the rollers are carefully designed and can be adjusted through each independent hand wheel. 4. The delicate design of the printing unit ensures accurate printing and therefore, CI type is suitable for delicate patterns and chromatic printing. | 1. The ink system takes the ceramic anilox roller and scrapping blade design, which are more expensive than the steel ink roller design. 2. CI type can only print on one side of the material. 3. The scrapping blades are wearable parts and need to be changed frequently. |

Our features&solutions:

1. We will add on the machine independent heating system and fan to speed up the ink drying and avoid color stain.

2. Each printing unit will be added with rectifying function to ensure printing accuracy.

3. Independent ink roller motor is added to keep the ink roller running at a slow speed to save ink waste and prolong the service life of the machine.

4. We offer trains for the operators or overseas installation and maintain service.